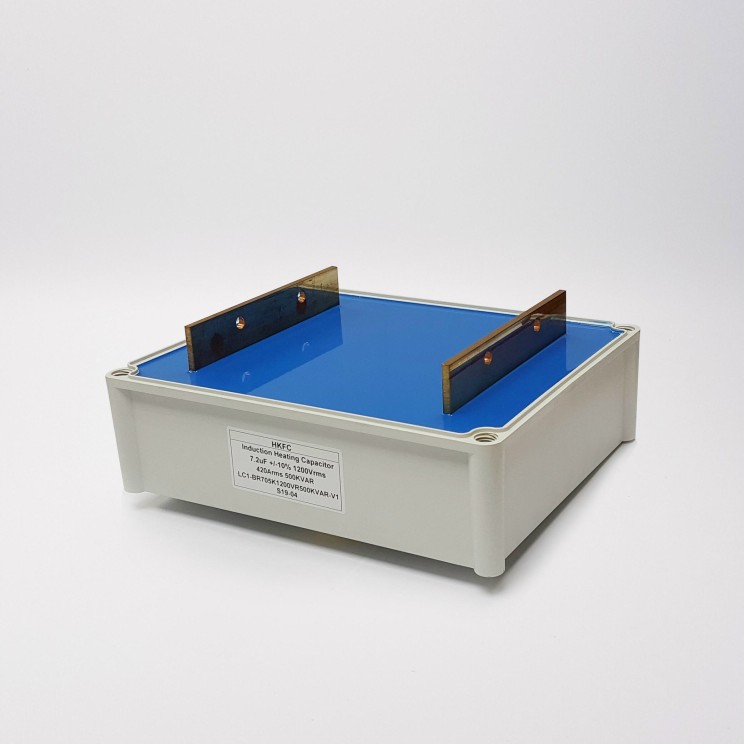

Induction Heating Capacitor LC1-BR LC2-BR LC3-BR series :

Durable Plastic Enclosure, Dry design with Heavy Duty Busbars for High Current and High Power connections.

This series of capacitors is for medium frequency range high current applications with low self-heating characteristics. Our capacitors can improve customers’ furnace/oven heating efficiency. Eventually, end customers can save electricity costs kWh.

Typical Applications :

Induction heating power supplies, Induction Heating/Melting Equipment, Resonant Circuits, Tank Circuits and High Continuous AC Current applications, High Current Welding and High Current Power Supplies.

Electrical Characteristics :

This series of capacitors is Plastic Enclosure, Dry construction design and doesn’t have leakage problem when compared with traditional Metal Enclosure Oil impregnated capacitors.

Our capacitors are Higher Insulation Resistance and Lower Leakage Current, when compared with Metal-Can Capacitors.

Continuous AC Current Duty with ambient Temperature up to +85C

High Reactive Power

Ultra Low ESR, ESL and Internal loss

High Insulation Resistance and Low Leakage Current

Low self heating

Capacitance range : 0.5uF – 20uF ( can be customized )

Rated Voltage : 1000Vrms – 5,500Vrms ( can be customized )

Ripple RMS Current up to 800Arms

Reactive Power up to 800kVAR

Operating Temperature ranges : +70C / +85C and support +105C requirement

Doesn’t need Water Cooling

Force Air Cooling can be useful but not a must

We support AC Current Capacitor with integrated Thermocouples. The thermocouple output can be as one of the control signals and trigger protective functions.

HKFC manufactures High Current Induction Heating Capacitors with different rated Capacitance, AC Voltages, RMS Current, Reactive Power, Frequency ranges, size restriction, temperature ranges and even with capacitor configuration options.

Similar circuit designs can have very different capacitor electrical and mechanical profile requirements. Please feel free to send your application details to us for a capacitor suggestion and quotation.

There are more technical notes on the Application, Plastic vs Metal Encased Capacitor and Installation pages.

Our average production lead time is about 1 – 3 months, depending on order quantity, material and production status.

Accept small, bulk quantity orders and PayPal..

Other similar continuous current capacitors.